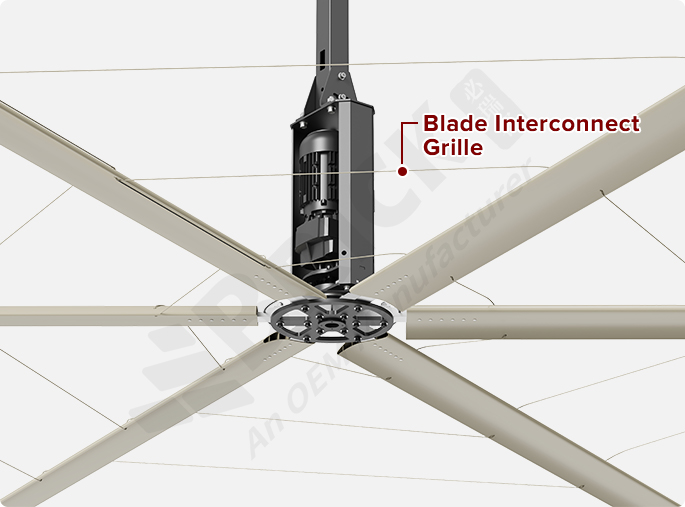

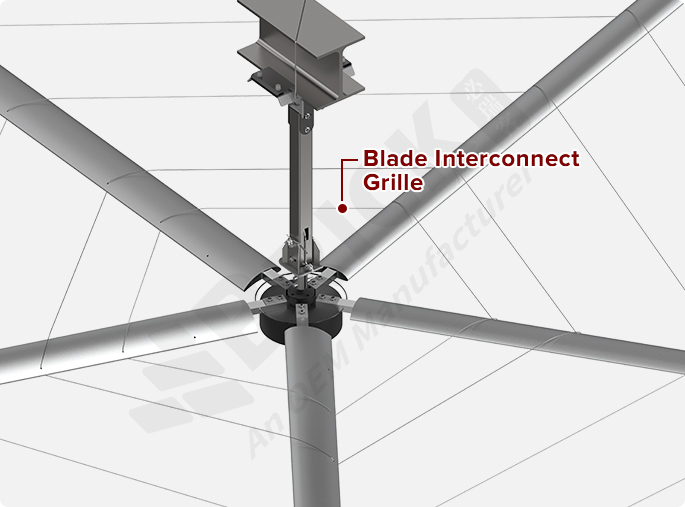

The unique feature of Blade Interconnect Grille is its revolutionary concept: “Blades Protect Blade”!

In normal applications, goods always be protected by external grille. For HVLS Ceiling Fans, external grille would be cost, complicated and time-consuming as no convenient facilities or bearing places to hang grille. Besides, in most cases workshops which have Bridge Crane would leave few spaces to install the grille, and a huge grille would have a negative influence on clean and tidy.

Blade Interconnect Grille consists of blades and several nylon rings.

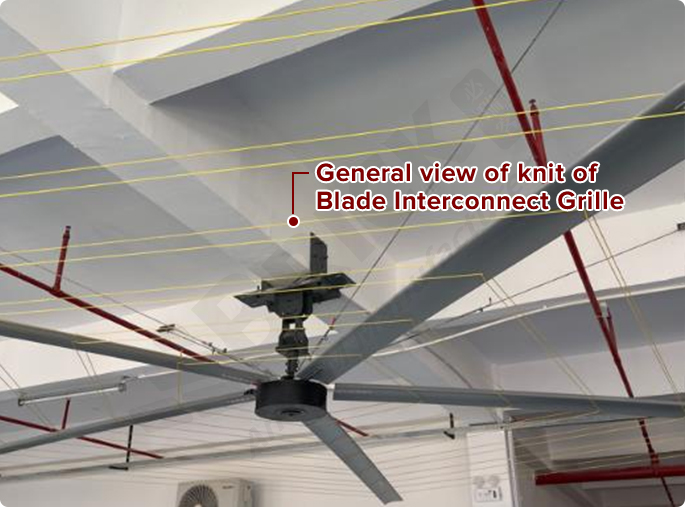

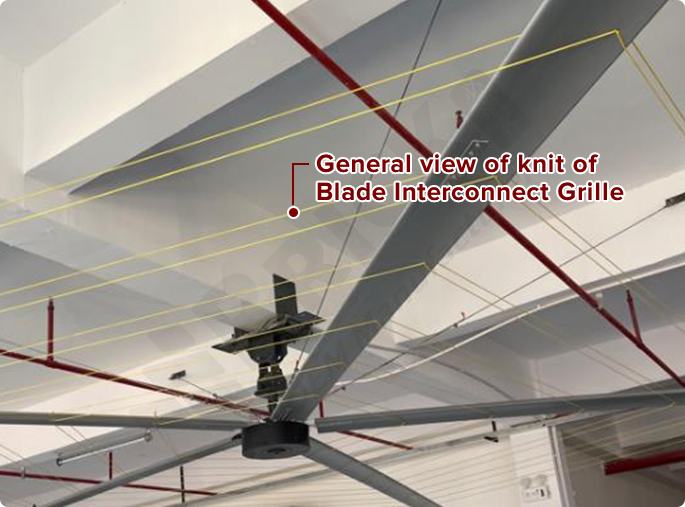

A nylon cord goes through the blades one by one and interconnects them to form a ring. 3-5 such rings along the radial make up a protective grille.

In case one blade broken or flyoff, the adjacent functional blades will grab the failure one. Actual testing shows the failure blade was floated and swung which was easy to identified.

A single φ2mm nylon cord can sustain over 60 kg tensile force, while the weight of a single blade is less than 6 kg. the nylon cord meets the requirement. Besides, the 7300 mm HVLS Fan needs about 90 meters nylon cord to knit the grille, about 0.34 kg, the grille will not increase the load.

Two cords, up and down, knit together through blade hole like sewing machine, easy and convenient.